干式无油螺杆式空气压缩机:终极指南

When it comes to industrial air compressors, the dry 无油螺杆式空气压缩机 stands out for its efficiency, reliability, and cleanliness.

But how does it work, and what are its advantages and disadvantages ? Let's dive into the basics and explore the world of dry oil-free screw compressors,

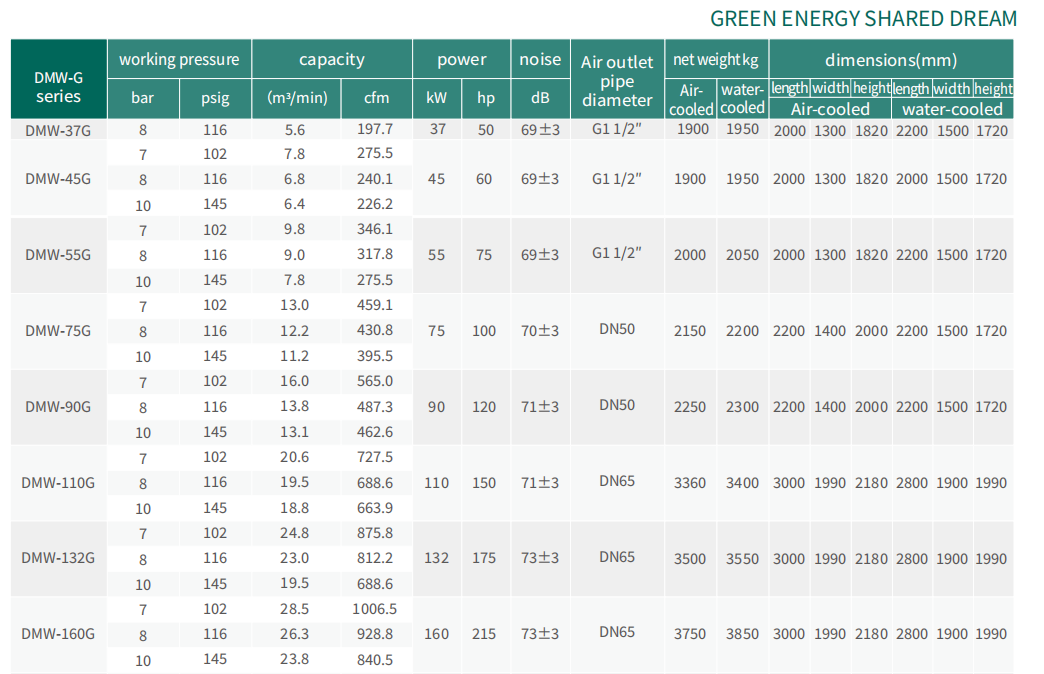

with a special focus on the DREAM air compressor 型号: DMW-G 系列.

How Does a Dry 无油螺杆式空气压缩机 Work?

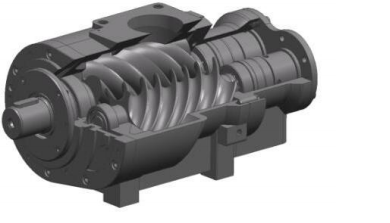

A dry 无油螺杆式空气压缩机 uses two intermeshing helical screws (rotors) to compress air. As these screws rotate, they trap and compress the air between them,

forcing it through a discharge port at high pressure. Unlike lubricated compressors, dry oil-free models do not use oil to seal or cool the compression chamber,

ensuring that the compressed air remains clean and free of contaminants.

The screws are precision-engineered to minimize friction and wear, allowing for continuous, efficient operation.

The compressed air then passes through a cooling system and is often filtered further to remove any trace impurities before being delivered to the end-use application.

Advantages of Dry Oil-Free Screw Compressors

Clean Air Output: The absence of oil means the compressed air is free from contaminants, ideal for sensitive applications like food processing, medical,

and pharmaceutical industries.

Maintenance-Free: No oil means fewer parts to maintain, reducing downtime and maintenance costs.

Longevity: Dry screw compressors typically have a longer lifespan due to reduced wear and tear.

Energy Efficiency: Modern designs offer high volumetric efficiency, converting more electrical energy into compressed air.

Reliability: The simple, robust design minimizes the risk of failures, ensuring consistent performance.

Disadvantages

Higher Initial Cost: Dry oil-free compressors tend to be more expensive upfront compared to lubricated models.

Operating Temperature Limits: They may require additional cooling systems to manage the heat generated during compression.

Sensitivity to Particle Contamination: The seals and bearings are sensitive to dirt and debris, necessitating clean operating environments.

Introducing the DREAM air compressor 型号: DMW-G 系列

When it comes to dry oil-free screw compressors, the DREAM air compressor 型号: DMW-G 系列 stands out with its innovative features and exceptional performance.

Here’s why the DMW-G 系列 is a game-changer:

High Efficiency: Engineered for maximum volumetric efficiency, the DMW-G 系列 minimizes energy consumption, reducing your operational costs.

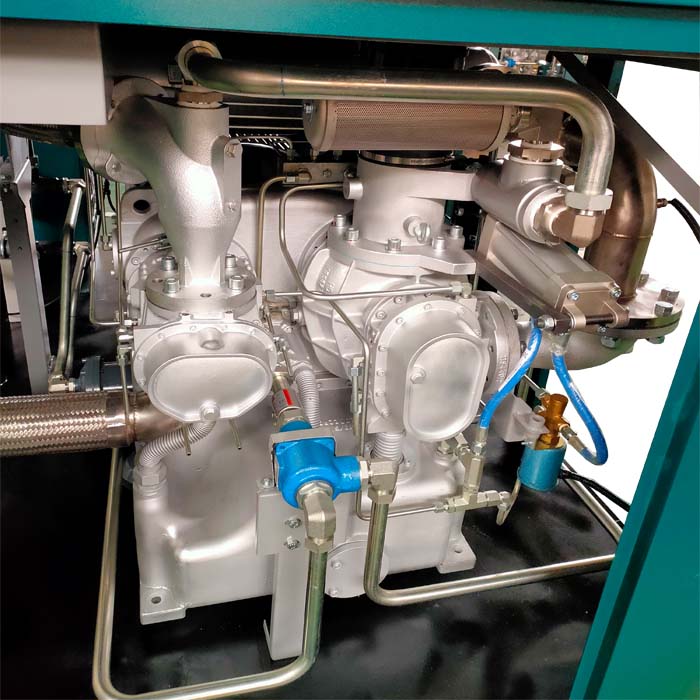

Robust Design: Built with precision and durability in mind, the compressor can handle heavy-duty applications with ease.

Quiet Operation: Advanced noise reduction technology ensures the compressor runs quietly, making it ideal for environments where noise is a concern.

Intelligent Controls: Equipped with smart control systems, the DMW-G 系列 offers real-time monitoring and diagnostics, making maintenance and troubleshooting a breeze.

Compact Footprint: Designed to save space, the compressor’s compact footprint allows for easy installation in even the most constrained environments.

Environmentally Friendly: With zero oil emissions, the DMW-G 系列 contributes to a cleaner, greener work environment.

Visit the product page to learn more about the DMW-G 系列 and explore its specifications.

By understanding the basics and exploring the benefits and drawbacks of dry oil-free screw compressors, you can make an informed decision about the best compressed air

solution for your needs.